Hydraulic presses are widely used in the production of Sheet Moulding Compound (SMC), a composite material made of a mixture of resin and reinforcement fibers. The use of hydraulic presses in the compression of SMC allows for the production of high-quality, consistent parts with precise dimensional accuracy.

SMC is a cost-effective alternative to traditional metal forming processes, as it requires less energy and labor to produce parts, and can also result in lighter weight and improved surface finishes.

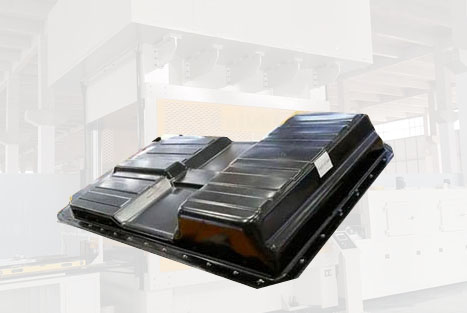

The compression process for SMC involves placing the mixture of resin and reinforcement fibers into a mold, which is then closed by the hydraulic press. The high-pressure fluid from the press exerts force on the material, causing it to flow and fill the mold. The material is then cured under pressure, resulting in a solid part.

We are not only offering SMC Hydraulic Press Solutions also offer Hot Forging Press, Forming Press, Metal Forming Press etc. If you have any need about hydraulic press, please contact with us to get more information.

SMC is a cost-effective alternative to traditional metal forming processes, as it requires less energy and labor to produce parts, and can also result in lighter weight and improved surface finishes.

The compression process for SMC involves placing the mixture of resin and reinforcement fibers into a mold, which is then closed by the hydraulic press. The high-pressure fluid from the press exerts force on the material, causing it to flow and fill the mold. The material is then cured under pressure, resulting in a solid part.

We are not only offering SMC Hydraulic Press Solutions also offer Hot Forging Press, Forming Press, Metal Forming Press etc. If you have any need about hydraulic press, please contact with us to get more information.

+86-13509801050

+86-13509801050

E-mail

E-mail