When designing a hydraulic press, there are 3 core key elements to consider: performance parameters, structural design and control system.

Customized hydraulic presses are essential for meeting specific industrial or manufacturing needs that standard models cannot fulfill. We are specialized in making hydraulic presses with the capacities, measurements and technical characteristics adapted to your needs from 5 up to 5000 tons. Custom-made hydraulic presses are our expertise and they have the high, long-lasting quality that GOODSJACK is known for.

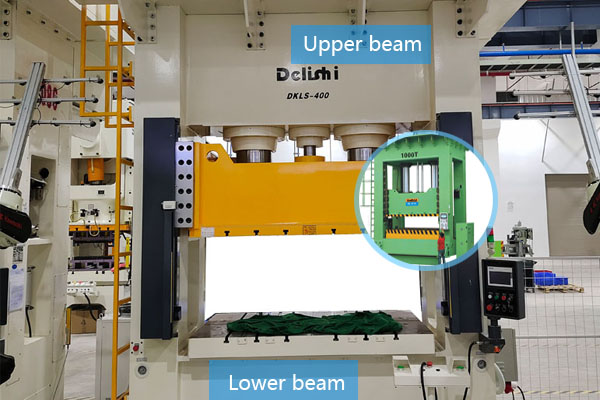

The development of a new double-beam hydraulic press involves several critical steps, including structural design and topology optimization.

Hydraulic presses are powerful machines that require strict safety precautions to prevent accidents and injuries.

On January 12, 2025, Guangdong Delishi Technology Co., Ltd. welcomed the highly - anticipated groundbreaking ceremony for its new factory. The site was bustling with activity as employees, partners, and local dignitaries gathered together to witness this significant moment. The air was filled with vibrant energy and anticipation for the future.

Today, our four column hydraulic press was packaged and shipping to Polan.

The four corner leveling system of hydraulic press is an important device used to ensure that the hydraulic press slide remains level during movement.

Congratulation our guide rail hydraulic machine shipment on time. Although the factory is fully booked with orders up to next year, we still produce according to schedule, inspect and proof-sample the products before delivery, and arrange shipment on time.

4 post hydraulic press is a kind of mechanical equipment that uses the static pressure of hydraulic oil to be transported by oil pump to process metal, plastic, rubber, wood, powder and other products. The optimal design scheme of the 4 post hydraulic press can be adjusted and improved according to the actual situation.

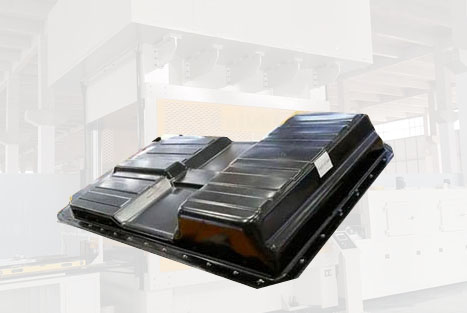

Hydroforming press for new energy liquid cooling plate is an advanced manufacturing process, mainly used to produce liquid cooling plates and other heat dissipation components. Because of the variety of cell shapes and more importantly the different temperature distributions within the cells, thermal management solutions need to be flexible.

Cold forging hydraulic press for copper terminal lug, is to press copper material into a terminal of a specific shape by a hydraulic press. The specific forming process may vary depending on the shape and requirements of the terminal.

Goodsjack/Delishi Hydraulic Machinery specializes in the production and sales of various specifications and models of hydraulic presses, including 5000T hydraulic presses. This type of hydraulic press has strong bearing capacity and stable operation performance, and is suitable for large-scale metal processing, stamping, cold extrusion and other processes.

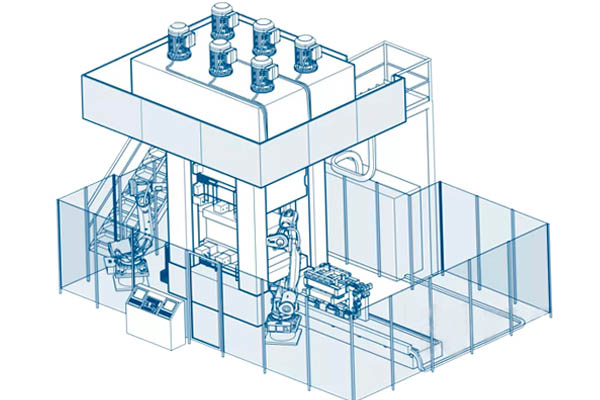

We are not only offering SMC Hydraulic Press Solutions also offer Hot Forging Press, Forming Press, Metal Forming Press etc. Our SMC Hydraulic Press is highly productive, durable and can be availed in capacities ranging from 50 Ton to 5000 Ton as per the requirements. Our hydraulic press machinery realizes that facilitate the action reliability, security and stability, and we can customize wider and higher SMC Press according to customers' requirements.

Four column hydraulic presses are used in a wide range of applications:metal forming,plastic products processing,powder metallurgy etc.

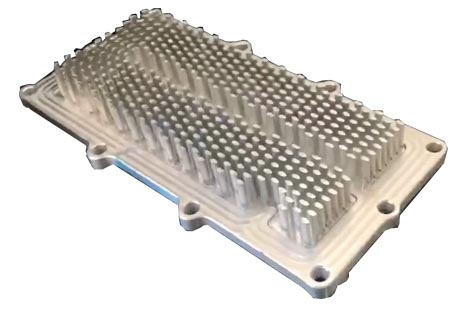

The Pin Fin heat sink was made by a new manufacturing process "forging", with hydraulic cold forging press.Hydraulic cold forging press is a highly precise manufacturing process equipment, the workpiece is formed under high pressure and low temperature.