On January 12, 2025, Guangdong Delishi Technology Co., Ltd. welcomed the highly - anticipated groundbreaking ceremony for its new factory. The site was bustling with activity as employees, partners, and local dignitaries gathered together to witness this significant moment. The air was filled with vibrant energy and anticipation for the future.

Today, our four column hydraulic press was packaged and shipping to Polan.

Congratulation our guide rail hydraulic machine shipment on time. Although the factory is fully booked with orders up to next year, we still produce according to schedule, inspect and proof-sample the products before delivery, and arrange shipment on time.

Hydroforming press for new energy liquid cooling plate is an advanced manufacturing process, mainly used to produce liquid cooling plates and other heat dissipation components. Because of the variety of cell shapes and more importantly the different temperature distributions within the cells, thermal management solutions need to be flexible.

Goodsjack/Delishi Hydraulic Machinery specializes in the production and sales of various specifications and models of hydraulic presses, including 5000T hydraulic presses. This type of hydraulic press has strong bearing capacity and stable operation performance, and is suitable for large-scale metal processing, stamping, cold extrusion and other processes.

We are not only offering SMC Hydraulic Press Solutions also offer Hot Forging Press, Forming Press, Metal Forming Press etc. Our SMC Hydraulic Press is highly productive, durable and can be availed in capacities ranging from 50 Ton to 5000 Ton as per the requirements. Our hydraulic press machinery realizes that facilitate the action reliability, security and stability, and we can customize wider and higher SMC Press according to customers' requirements.

As a leader in the hydraulic press machine industry, Delishi has become a leader in the industry with its excellent product quality and innovative technology as the cornerstone.

Delishi Machinery Attended in 2023 World Hydrogen Technology Convention

The knockout cylinder is an additional device of the hydraulic press machine. It is mainly used to punch down the punching waste during the punching process. Therefore, not all processing techniques require the installation of a feeding cylinder for the hydraulic press machine, which can be determined according to production needs.

The price factor of the 500 ton hydraulic press will affect the customer's purchase intention, as well as the quality of the hydraulic press machine.

Hydraulic heated platen presses for composites forming is a kind of hot pressing molding sample of carbon fiber composite material specially processed.The hydraulic press machine also heated platen presses the material into a lattice characteristic for craftsmanship, new energy, new material molding and process development solutions.

The aluminum alloy ball head is a kind of cue connecting piece, and its manufacturing process includes cold extrusion forming and forging forming. Following, we will introduce hydraulic cold extrusion press for aluminum alloy ball heads.

Heat sink cold extrusion press machine is an advanced technology used in the manufacturing of heat sinks. By using this technology, heat sink manufacturers can produce heat sinks with excellent thermal conductivity and durability. In this article, we will discuss the working principle of a heat sink cold extrusion machine and its benefits.

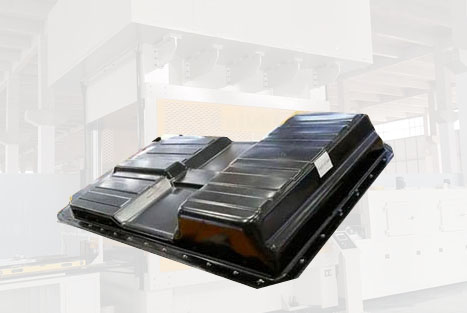

With the rapid development of new energy vehicles, the automotive industry's demand for battery performance is also increasing. Intense market competition has made new energy vehicle manufacturers have higher requirements on the performance of vehicle batteries to ensure the battery life and service life of the vehicle.

The frame hot forging press adopts a frame structure with high guiding precision, good rigidity and strong anti-deflection force. It is especially suitable for pressing asymmetrical products.