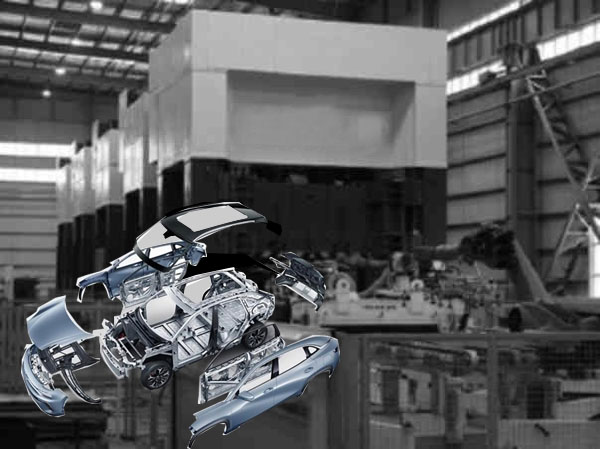

On the basis of industry-university-research cooperation, comprehensive use of mechanical, control, testing, hydraulic and other multidisciplinary technologies, after more than 20 years of efforts, a number of keys in the hydraulic press flexible production line have been studied technology and integrated development applications. On the basis of summarizing the existing design experience of large-scale hydraulic machine tools, this project innovatively applies proportional servo control technology to develop a product that meets the needs of rapid stamping of thin plates.

Special hydraulic system for drawing process, stamping speed up to 800mm/s. The control system of hydraulic press flexible production line, based on fieldbus was developed, and the quick mold change system and destacking were integrated machine, cleaning machine, centering equipment, loading and unloading robot and other equipment, forming a flexible production line with complete functions, can complete a variety of precision stamping process of large automotive cover parts, to meet the domestic requirements.

Multi-variety, small-batch production mode of automobiles. The original design of the top-mounted electric synchronous adjustment of the full tonnage low-noise punching buffer device, so that the punching tonnage is increased from 60% of the nominal force 100%, increasing the punching processing capacity. In view of the problem of stamping process defects caused by the asymmetry and real-time change of die crimping force in the past, the closed-loop proportional adjustment of the four corners of the hydraulic stretching pad was studied.

The pressure and variable pressure control technology effectively solves the bottleneck that the tensile quality of precision and complex asymmetrical workpieces is difficult to guarantee, and the scrap rate of stamping parts is greatly reduced. The development of hydraulic press flexible production line has the characteristics of good processing quality, high efficiency, flexibility and high degree of automation, and has been successfully used in many manufacturers such as BYD, SECOND AUTOMOBILE, SAIC, JAC, Geely, Lifan, etc. The low cost of automobile manufacturing has effectively promoted the development of China's automobile industry.

Delishi hydraulic press flexible production line mainly applied to: metal materials cold extrusion, stamping, light stretching, blanking and other purposes. Strentch forming large products, such as car body panels, auto parts, interior parts etc.

+86-13509801050

+86-13509801050

E-mail

E-mail