Structural principle of frame hydraulic press

The frame hydraulic press is composed of upper and lower beams, columns and workbenches, and the overall structure is a closed frame. Its main working principle is to generate pressure through the hydraulic cylinder and drive the pressure head or mold to press the workpiece. Due to the rigidity of its frame structure, it can withstand large pressing forces and loads.

Frame hydraulic press application

Precision parts processing: such as automotive parts, aerospace parts, etc., require high-precision and high-strength pressing operations.

Stamping and forming: the process of stamping, forming, and bending sheet metal.

Powder metallurgy: the pressing and molding of powder materials.

Advantages of frame hydraulic press

Stable structure: The overall frame structure has good rigidity and can withstand large compressive force.

High precision: suitable for high-precision machining, high repeatability and positioning accuracy.

High safety: usually equipped with a complete safety device.

Disadvantages of frame hydraulic press

Higher cost: Higher design and manufacturing costs and larger initial investment.

Complex maintenance: The structure is complex, and repair and maintenance are relatively difficult.

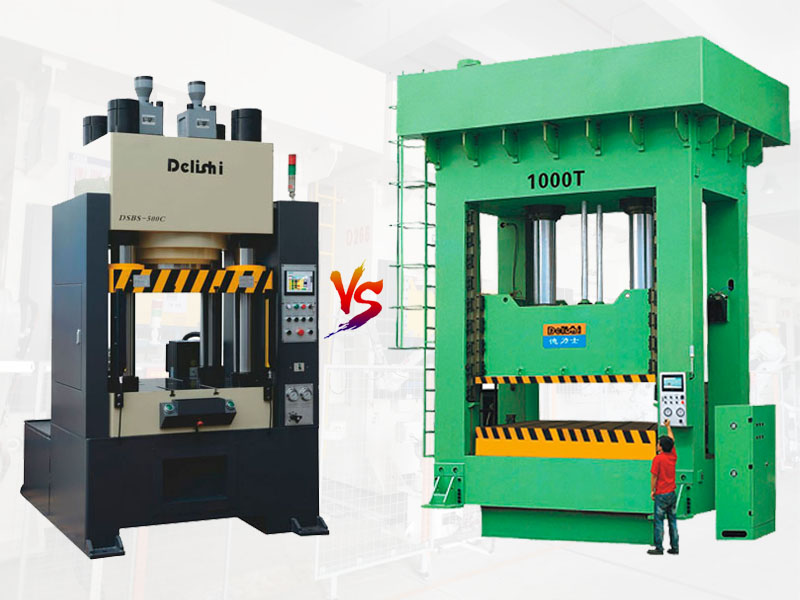

Structural principle of four column hydraulic press

The four-column hydraulic press is composed of upper and lower beams, four columns and a workbench, and the four columns connect the upper and lower beams together to form an open frame. Hydraulic cylinders are usually mounted on the upper cross beam and press the workpiece by driving the pressure head or die.

Four column hydraulic press application

Sheet metal processing: stamping, forming and shearing of sheet metal.

Rubber products processing: pressing and molding of rubber parts.

Plastic products processing: compression molding of thermoplastics.

Advantages of four column hydraulic press

Simple structure: low design and manufacturing costs.

Versatility: It is suitable for a variety of pressing processes and has a wide range of applications.

Easy to maintain: simple structure, easy to repair and maintain.

Disadvantages of four column hydraulic press

Poor rigidity: The overall rigidity is not as good as that of frame hydraulic presses, and there may be deformation when subjected to large loads.

Relatively low accuracy: The accuracy and repeatability are not as good as those of frame hydraulic presses.

Select Recommendations of which one type hydraulic press machine is suitable for you.

High-precision requirements: If high-precision and high-strength pressing processing is required, it is recommended to choose a frame hydraulic press.

Cost and versatility: If you have a limited budget and need a high degree of versatility of the equipment, a four-column hydraulic press is a more suitable choice.

Load and pressure requirements: Frame hydraulics perform better in applications that require higher loads and pressures.

+86-13509801050

+86-13509801050

E-mail

E-mail