Power system operation:

The power source of the deep drawing hydraulic press is usually an electric motor, which drives the hydraulic pump to operate. The hydraulic pump sucks hydraulic oil from the oil tank and converts it into a fluid with a certain pressure. For example, in the process of deep drawing and forming automotive parts, the motor starts and drives the hydraulic pump to start working, providing a power basis for subsequent stretching actions.

Hydraulic oil transmission:

The high-pressure oil output by the hydraulic pump is transported to the working cylinder or oil cylinder of the hydraulic press through hydraulic pipelines. These pipelines serve to connect various hydraulic components to ensure that the hydraulic oil can be accurately transmitted to the required position.

Action in the oil cylinder:

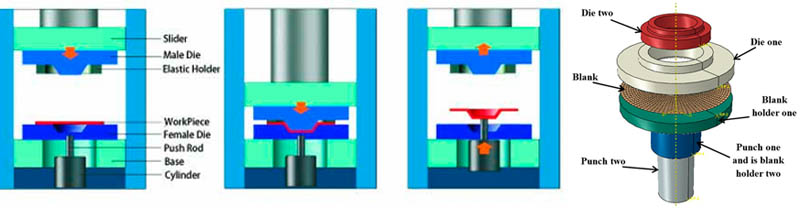

When the high-pressure oil enters the oil cylinder, it pushes the piston in the oil cylinder to move. The piston is connected to the stretching mechanism, and the movement of the piston drives the stretching mechanism to produce a stretching action. In this process, the pressure energy of the liquid is converted into the mechanical energy of the piston, thereby realizing the stretching of the workpiece.

If it is a double-acting thin plate stretching hydraulic press, there are generally two cylinders working together, one cylinder is used to push the movable crossbeam downward to contact the workpiece, and the other cylinder provides the stretching force; while the single-acting thin plate stretching hydraulic press usually has only one cylinder to complete the stretching action.

Control during the stretching process:

In order to ensure the accuracy and stability of the deep drawing process, the deep drawing hydraulic press is usually equipped with various control valves, such as overflow valves, reversing valves, etc. The overflow valve can adjust the pressure of the system to prevent excessive pressure from damaging the equipment; the reversing valve is used to control the flow direction of the hydraulic oil, thereby changing the movement direction of the piston.

In addition, some advanced deep drawing hydraulic presses are also equipped with sensors and control systems, which can monitor and control the pressure, displacement, speed and other parameters in the stretching process in real time to ensure that the stretching effect meets the requirements.

Reset after deep drawing:

When the deep drawing work is completed, the pressure in the hydraulic system is gradually released, and the piston returns to the initial position under the action of the spring or other reset device, waiting for the next deep drawing operation.

Delishi/Goodsjack Hydraulic Machinery can supply deep drawing hydraulic press solution, including four column deep drawing press and frame hydraulic deep drawing press.

- Deep Drawing Hydraulic Press

Tags :

+86-13509801050

+86-13509801050

E-mail

E-mail