Features of Delishi/Goodsjack IGBT Heat Sink Cold Forging Extrusion Press

The use of a servo control system guarantee us to save 50-70% energy compared to a standard press.

Pressure stability,pressure error ±1bar,repeatable positioning accuracy up to±0.02mm.

Low failure rate,automatic alarm and fault indication,one-button reset function.

Remote maintenance service can be realized.

Can set up multi-stage pressure, multi-speed and contiouns fixed-pressure function.

Adopting an integral frame structure, high strength, low distortion and durability.

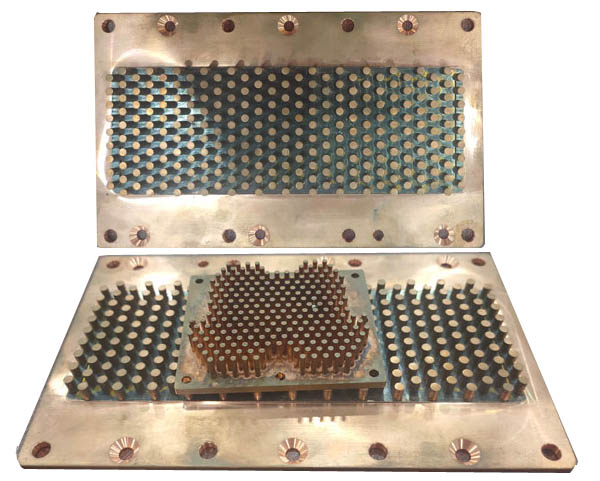

As the leading manufacturer of IGBT Heat Sink Cold Forging Extrusion Press, Delishi/Goodsjack obtained trust from clients for supplying and manufacturing reliable heatsink products. We stocked hundreds of numerous cold forging heat sink to fully support your business.

+86-13509801050

+86-13509801050

E-mail

E-mail