Home >

News >

Industry News >

Three-beam Four-column Deep Drawing Hydraulic Press with Side Press Cylinder

Three-beam Four-column Deep Drawing Hydraulic Press with Side Press Cylinder

Date:2023-03-08

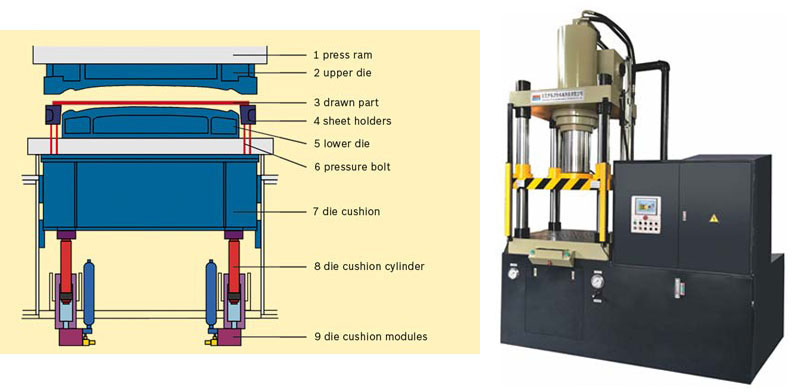

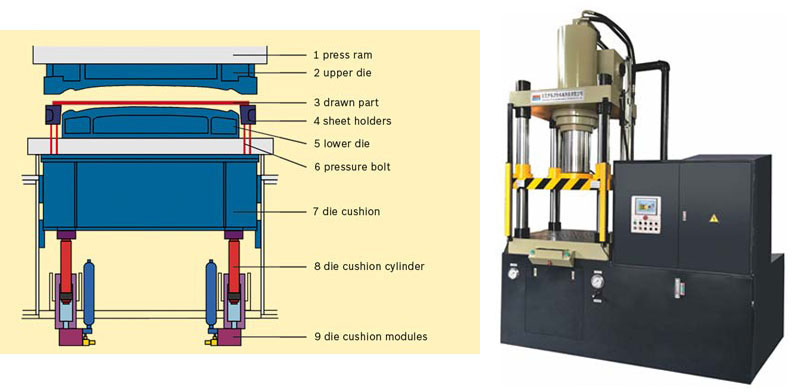

The deep drawing hydraulic press (thick and thin plate deep drawing machine) of this structure is mostly suitable for products with relatively large and round workpieces. For example, the head, large car cover, stainless steel, etc., belong to the deep drawing process. The equipment adopts a three-beam and four-column structure, which is compact and beautiful. The beam is welded by high-quality steel plates and tempered to eliminate the internal stress of the structure. High, not easy to deform. The oil cylinder is divided into the main oil cylinder and four edge cylinders. The main oil cylinder provides the tensile force, and the four edge cylinders push the sliding beam to provide the edge force. Under the precise control of the proportional flow valve and the servo system, the pressure configuration is adjusted reasonably to achieve Expected molding effect, smooth surface, no wrinkles, uniform thickness, small error in roundness accuracy. The side press cylinder of the three-beam four-column deep drawing hydraulic press can be used as a buffer device, and can also be used for blanking and punching. Under the pressure set by the system, the working pressure of each cavity can be adjusted separately. In order to ensure the quality of stretching and blank-holding, a pressure-holding system of a blank-holding cylinder is added.

The three-beam four-column deep drawing hydraulic press (thick and thin plate deep drawing machine) with a blank holder cylinder has a main cylinder, a frame, a blank holder cylinder, a material return cylinder, a movable beam, a workbench, a thimble, a lower pallet, a lower cylinder and a hydraulic pressure system composition. The deep drawing process is as follows: the main cylinder goes down quickly—the main cylinder turns slowly to profiling—the main cylinder draws, the lower cylinder passively provides blank holder force—the drawing is in place—the main cylinder depressurizes and returns, and the lower cylinder returns.

+86-13509801050

+86-13509801050

E-mail

E-mail