Difference Between Hot Isostatic Pressing and Hot Pressing

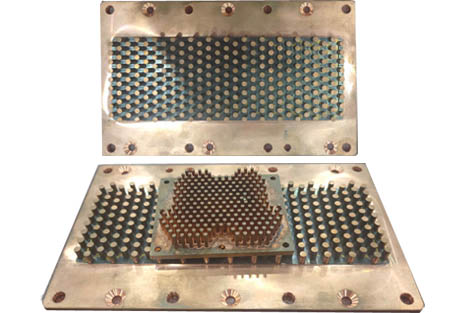

The IGBT heat sink cold forging extrusion press is a specialized machine used in the manufacturing process of IGBT (Insulated Gate Bipolar Transistor) heat sinks. IGBT Heat Sink Cold Forging Extrusion Press of Delishi/Goodsjack Hydraulic Machinery, is specially designed and made for forming in one punch.

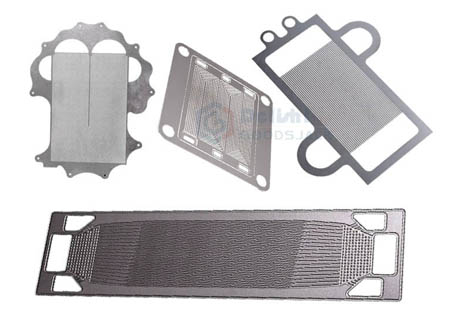

As global demand for clean and sustainable energy surges, Delishi/Goodsjack Hydraulic Machinery is your premier partner in manufacturing metal flow field and cooling plates essential for hydrogen fuel cells and hydrogen generation. Our hydraulic press machine which pressing metal bipolar of hydrogen fuel cells,flow field plates deliver outstanding electrical and thermal conductivity, featuring channel customization option enhance output and efficiency.

As a leader in the hydraulic press machine industry, Delishi has become a leader in the industry with its excellent product quality and innovative technology as the cornerstone.

The hydraulic press flexible production line can solve the stamping processing of large cover parts with complex shape, large stretch ratio and high precision, which is an important hydraulic press machine to ensure the quality of automobiles.

Hydraulic press machine is a machine using a hydraulic cylinder to generate a compressive force. As a metal fabricator or manufacturer, maximizing the efficiency of your press brake can significantly impact your productivity and profitability. Here, we'll explore 10 Ways to maximize efficiency with your hydraulic press machine operations, optimizing your workflow and achieving better results.

What exactly is a mould temperature controller of carbon fiber hydraulic press? The mould temperature controller is an important piece of equipment during the use of the carbon fiber hydraulic press.

Through years of development of hydraulic presses, the hydraulic press has designed a four-column guide structure and a frame guide structure.

Water bulging formed products require welding, while deep drawing formed products are a whole. The water bulging process and the deep drawing process each have their own advantages and disadvantages, and the specific choice of process depends on factors such as the required manufacturing shape, production efficiency, and cost. If you need hydraulic press machine, please contact us, the best hydraulic press solution will be provided for you.

The Latest Development Trends in Hydraulic Press Machine Industry, the Hydraulic Press Machine Market size is estimated to grow at a CAGR of 5.1% over the forecast period.

Advantages of hydraulic press machines: high pressure output and precision operation.As a commonly used industrial equipment, hydraulic press machine has unique advantages. It transfers energy in a liquid and converts it into mechanical motion, so it excels in some applications that require high pressure output and precision operation.

We must pay attention to the relevant operational requirements when installing main cylinder of hydraulic press machine, and the contact surface between the flange of the hydraulic cylinder and the beam should be in close contact with more than 80% of the area.

The hydraulic press machine its application range,Goodsjack/Delishi Hydraulic Machinery has already explained it at the beginning of the introduction of the hydraulic press machine.

When hydraulic oil overheating when using hydraulic press machine, we should check it regularly. Generally, the reasons that cause the hydraulic oil overheating are serious oil contamination, insufficient oil and insufficient heat dissipation, overflow parts of the system, local overheating, and cooling. System failure or high ambient temperature, as well as overloaded work, etc.

Hydraulic press machines can be used in forming, drawing, shaping, straightening, etc. Hydraulic oil is used to transfer energy, so there will be some vibration during operation. Some friends have misunderstandings, thinking that small hydraulic presses with small tonnage have large vibrations. However, large and heavy hydraulic presses will not vibrate due to their own tonnage. This is wrong. Today we will discuss with you how to effectively and correctly reduce vibration.