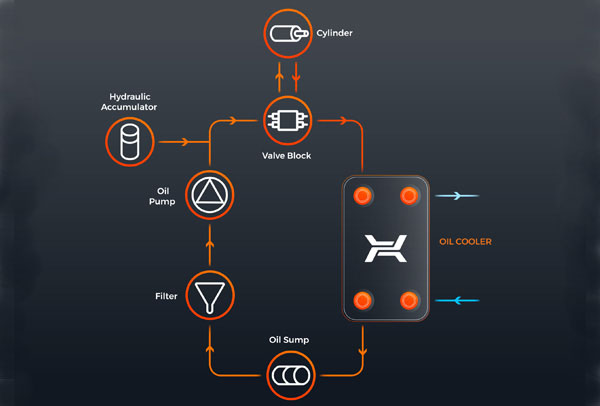

The function, performance requirements and installation method of the cooler in the hydraulic press, generally speaking, a oil cooler should be installed in the hydraulic system of the hydraulic press machine. Because the oil cooler plays a vital role in the hydraulic press machine.

Metal powder press is a machine designed to press metal powders into desired shapes and sizes. This metal power pressing machine utilizes mechanical and hydraulic forces to form metal powders into solid objects. The metal powder press is used in several industries, including aerospace, automotive, medical, and electronics, where metal powder is used for various applications.

The multi-direction die forging hydraulic press for water separator is a precision forging technology for split die forging on a multi-directional die forging hydraulic press, and its deformation is mainly extrusion. It is used for multi-directional forging and precision forging process of blanks, forgings, large, medium and small forgings.

There are many kinds of metal sculpture manufacturing process methods, and many machines and equipment are required. In the production and manufacturing process of copper sculptures, hydraulic presses will be used.

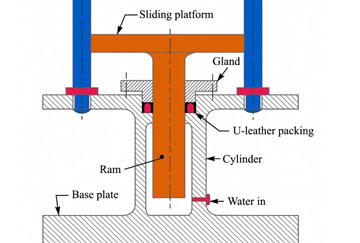

The deep drawing hydraulic press adopts a three-beam and four-column structure, which is compact and beautiful. The deep drawing process is as follows: the main cylinder goes down quickly—the main cylinder turns slowly to profiling—the main cylinder draws, the lower cylinder passively provides blank holder force—the drawing is in place—the main cylinder depressurizes and returns, and the lower cylinder returns.

Stretching the air conditioner oil separator, using a 200-ton four-column hydraulic press machine, one-time stretching and forming. The four-column hydraulic press machine is mainly used in the stretching process of the shell of the air-conditioning oil separator bottle. The selection of the hydraulic press machine is mainly based on the depth, size, size and shape of the stretched workpiece, and the selection of the appropriate stretching hydraulic machine model and the configuration of the hydraulic pad model. Stretching hydraulic presses are divided into deep drawing and shallow drawing. The shallow drawing technology can use ordinary hydraulic presses. The deep drawing technology requires the addition of ejector rods and hydraulic cushion devices.

500 ton hydraulic press, also known as 500 ton hydraulic press, is currently the most widely used model in processing enterprises. According to processing requirements, the machine structure can be designed and customized as 500-ton four-column hydraulic press, 500-ton frame-type hydraulic press, 500 ton single-column hydraulic press, etc., the machine It is widely used in the drawing, stamping, molding and hot forging of workpieces.

Regarding the use of the train door, it will cause the train door to bend and deform, which will cause safety problems. In order to cooperate with the correction and shaping of the train door panel, the hydraulic machine for correcting and shaping the train door panel has a large working surface.

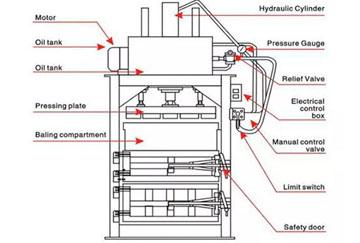

The hydraulic press machine consists of two parts: the main engine and the control mechanism. The main part of the hydraulic press machine includes the fuselage, the main cylinder, the ejector cylinder and the liquid filling device.

The 5000 ton hydraulic press is mainly used for hot forging processes of various forgings: billet upsetting, drawing, hot forging, die forging, reaming, bending, etc. It can also be used for drawing, blanking and bending of sheet metal parts , calibration and other processes.

Four-column servo hydraulic press machine is our hot selling machine. Following are features of four-column servo hydraulic press machine.Energy saving: Compared with the traditional hydraulic press, the electro-hydraulic servo-driven hydraulic press has remarkable energy-saving effect.

What is the reason why the hydraulic press machine falling too slowly? The first reason that comes to mind is the problem of hydraulic oil. Dirty oil has impurities and has not been replaced in time. Then the pump is broken and cannot absorb oil, or the valve unloading valve leaks oil. These faults may cause the sliding speed to be slow. When the hydraulic cylinder leaks oil, there is a problem with the oil leaking from the high pressure tank to the low pressure tank.

Some of the benefits of using hydraulic press machines for metal forming processes include:high precision and repeatability of finished parts.

Material savings is evident in the image of the shaft (above). The shaft on the below is machined out of bar stock and results in approximately 64% loss of material. The shaft on the above is formed and extruded to form a head and nose.