When designing a hydraulic press, there are 3 core key elements to consider: performance parameters, structural design and control system.

Customized hydraulic presses are essential for meeting specific industrial or manufacturing needs that standard models cannot fulfill. We are specialized in making hydraulic presses with the capacities, measurements and technical characteristics adapted to your needs from 5 up to 5000 tons. Custom-made hydraulic presses are our expertise and they have the high, long-lasting quality that GOODSJACK is known for.

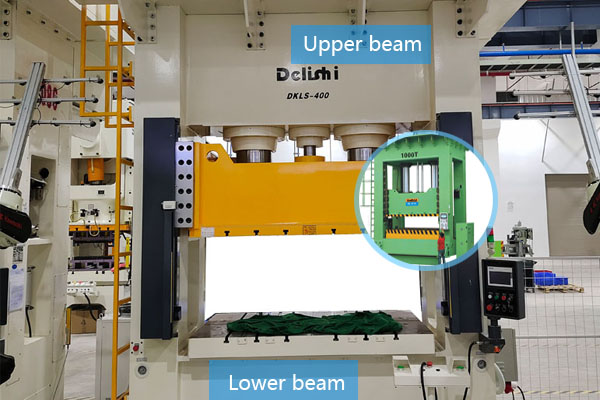

The development of a new double-beam hydraulic press involves several critical steps, including structural design and topology optimization.

Hydraulic presses are powerful machines that require strict safety precautions to prevent accidents and injuries.

The four corner leveling system of hydraulic press is an important device used to ensure that the hydraulic press slide remains level during movement.

4 post hydraulic press is a kind of mechanical equipment that uses the static pressure of hydraulic oil to be transported by oil pump to process metal, plastic, rubber, wood, powder and other products. The optimal design scheme of the 4 post hydraulic press can be adjusted and improved according to the actual situation.

Cold forging hydraulic press for copper terminal lug, is to press copper material into a terminal of a specific shape by a hydraulic press. The specific forming process may vary depending on the shape and requirements of the terminal.

Four column hydraulic presses are used in a wide range of applications:metal forming,plastic products processing,powder metallurgy etc.

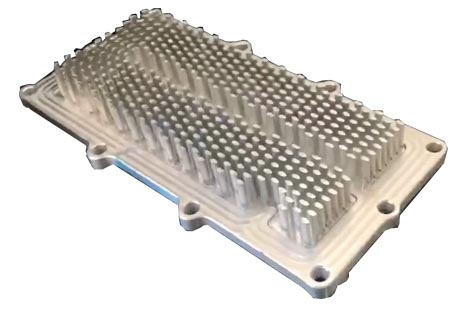

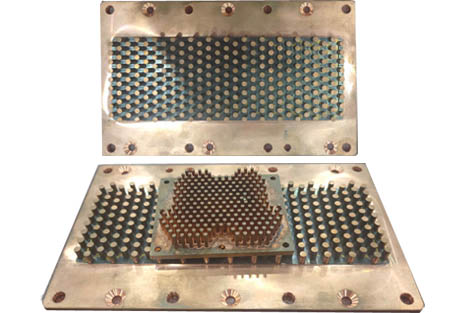

The Pin Fin heat sink was made by a new manufacturing process "forging", with hydraulic cold forging press.Hydraulic cold forging press is a highly precise manufacturing process equipment, the workpiece is formed under high pressure and low temperature.

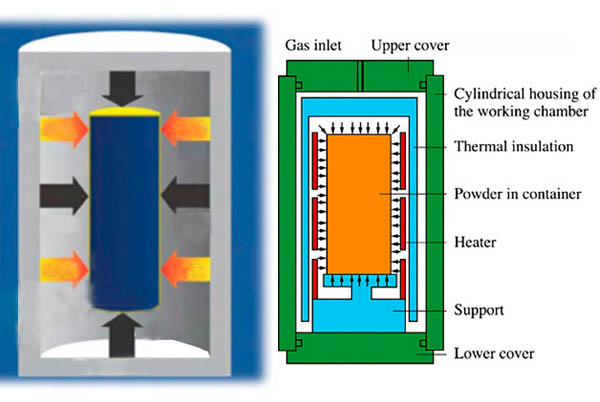

Difference Between Hot Isostatic Pressing and Hot Pressing

The IGBT heat sink cold forging extrusion press is a specialized machine used in the manufacturing process of IGBT (Insulated Gate Bipolar Transistor) heat sinks. IGBT Heat Sink Cold Forging Extrusion Press of Delishi/Goodsjack Hydraulic Machinery, is specially designed and made for forming in one punch.

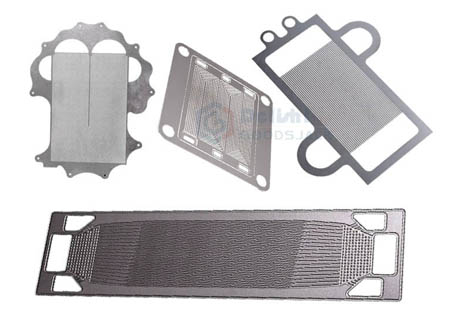

As global demand for clean and sustainable energy surges, Delishi/Goodsjack Hydraulic Machinery is your premier partner in manufacturing metal flow field and cooling plates essential for hydrogen fuel cells and hydrogen generation. Our hydraulic press machine which pressing metal bipolar of hydrogen fuel cells,flow field plates deliver outstanding electrical and thermal conductivity, featuring channel customization option enhance output and efficiency.

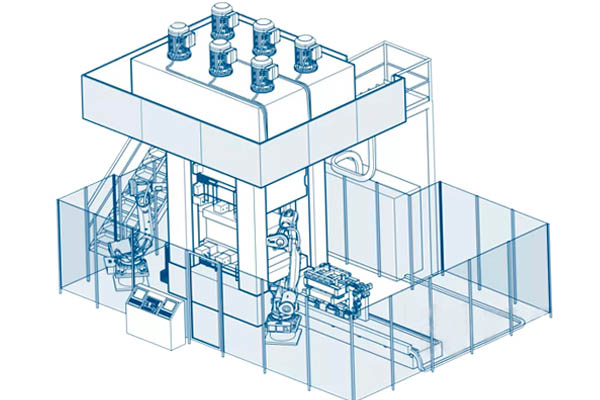

The hydraulic press flexible production line can solve the stamping processing of large cover parts with complex shape, large stretch ratio and high precision, which is an important hydraulic press machine to ensure the quality of automobiles.

Hydraulic press machine is a machine using a hydraulic cylinder to generate a compressive force. As a metal fabricator or manufacturer, maximizing the efficiency of your press brake can significantly impact your productivity and profitability. Here, we'll explore 10 Ways to maximize efficiency with your hydraulic press machine operations, optimizing your workflow and achieving better results.

What exactly is a mould temperature controller of carbon fiber hydraulic press? The mould temperature controller is an important piece of equipment during the use of the carbon fiber hydraulic press.